In the textile industry, maintaining consistent quality is paramount. One of the key factors that influence the durability and fit of textile products is fabric shrinkage. The Fabric Shrinkage Tester is an essential tool that allows manufacturers to accurately measure and control shrinkage, ensuring that the final products meet industry standards and customer expectations.

Why Fabric Shrinkage Matters

Fabric shrinkage occurs when a fabric reduces in size after exposure to processes like washing, drying, or even heat. This reduction can lead to poor fit, compromised fabric integrity, and dissatisfaction among consumers. For manufacturers, understanding and controlling shrinkage is vital to ensure that the end products remain true to size and shape, even after repeated use.

The Role of the Fabric Shrinkage Tester

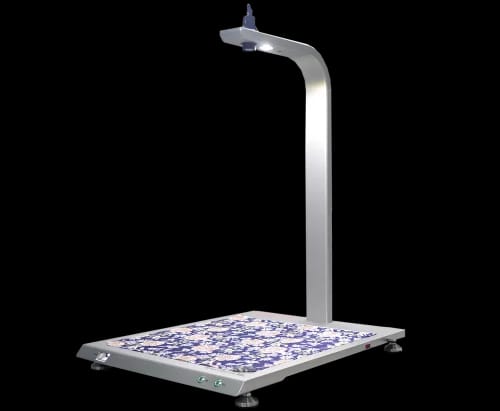

The Fabric Shrinkage Tester is a specialized device designed to measure the shrinkage rate of fabrics under controlled conditions. By simulating the washing and drying process, it provides precise data that helps manufacturers identify potential shrinkage issues early in the production process, allowing them to make necessary adjustments.

Key Features and Advantages

- Accurate Results: The tester offers high-precision measurements, ensuring that even the smallest changes in fabric dimensions are detected.

- User-Friendly Operation: Designed with simplicity in mind, the tester is easy to use, making it accessible to operators of all skill levels.

- Applicable to Various Fabrics: Whether testing natural fibers like cotton and linen or synthetic blends, the tester is versatile enough to handle a wide range of materials.

- Durability and Consistency: Built for long-term use, the tester provides reliable performance, making it a trusted tool in any quality control process.

Fabric Shrinkage Test Method

The shrinkage testing process typically involves marking a fabric sample using a shrinkage template, then subjecting it to standard washing and drying procedures. Afterward, the fabric’s dimensions are measured to determine the shrinkage percentage. The Fabric Shrinkage Tester automates and refines this process, minimizing the chances of human error and delivering consistent, repeatable results.

Importance of Adhering to Fabric Shrinkage Standards

Industry standards, such as those set by AATCC, ISO, and ASTM, outline acceptable levels of shrinkage for various fabric types. Adhering to these standards is crucial for maintaining product quality and customer satisfaction. The Fabric Shrinkage Tester helps manufacturers ensure that their fabrics meet or exceed these standards, ultimately contributing to the production of high-quality textiles.

Conclusion

Fabric shrinkage is a critical factor that can significantly impact the quality and performance of textile products. The Fabric Shrinkage Tester is an invaluable tool that helps manufacturers accurately measure and control shrinkage, ensuring that their products maintain their intended size, shape, and quality over time. By investing in this essential testing device, textile manufacturers can enhance their quality control processes, comply with industry standards, and deliver superior products that meet the demands of the market.

Keep an eye for more news & updates on Vents Fashion!